Transit-time ultrasonic flowmeters are among the most effective solutions for accurately monitoring the flow of liquids across a wide range of industrial sectors. In this article, we explain their operating principle, advantages, and typical applications.

How transit-time ultrasonic flowmeters work

Transit-time ultrasonic flow meters are measuring devices that determine the flow rate of a fluid within a pipe using high-frequency sound waves.

They are particularly well-suited for use with clean, single-phase fluids such as water or oils.

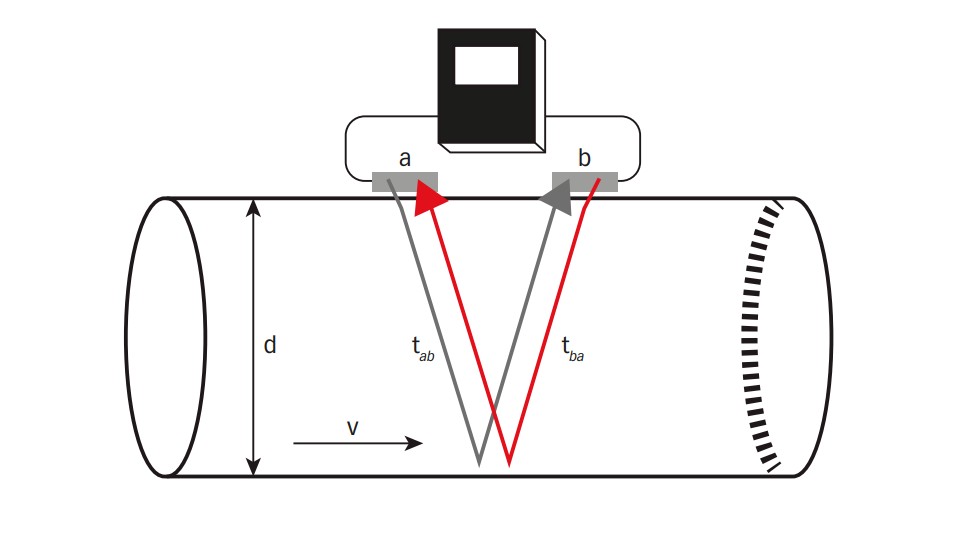

Their operation is based on the difference in transit time: two or more transducers (which act as both transmitters and receivers of ultrasonic signals) are positioned on the pipe.

When the fluid flows, the ultrasonic waves travel in opposite directions—one in the direction of the flow and the other against it.

The ultrasonic signal is affected by the flow of the fluid, experiencing acceleration in the direction of the flow and deceleration in the opposite direction.

The transit time difference measured by the sensors is directly proportional to the flow velocity, and by knowing the cross-sectional area of the pipe, the flow rate can be calculated. Under ideal conditions, transit-time ultrasonic devices can achieve measurement errors of less than 1%

Clamp-On and Full-Bore ultrasonic flowmeters

- Clamp-On flowmeters

Clamp-on ultrasonic flow meters are the ideal solution when it is not possible to interrupt the process, when pressure losses must be avoided, or when measuring particularly aggressive fluids.

These meters are installed externally on the pipe and are non-intrusive, which significantly reduces installation and maintenance costs. They can measure liquids with low solid particle content as well as gases, and due to their high versatility and wide range of available configurations, they are used in a broad spectrum of applications.

The figure illustrates a typical installation of clamp-on flow meters with V-path reflection, where the sensors are mounted on the same side of the pipe

- Full-Bore Meters

Full-bore ultrasonic flow meters are installed directly in line with the piping. Particularly suited for applications requiring extremely precise measurements, they involve more complex installation compared to clamp-on models but offer high accuracy even in applications involving non-conductive fluids.

Main Advantages

Among the most notable advantages of transit-time ultrasonic flow meters are their precision, the absence of moving parts (which reduces wear and the need for maintenance), their ability to measure bidirectional flow, and their adaptability to a wide range of operating conditions.

The fact that some models introduce no pressure loss into the system is another significant benefit in terms of efficiency.

An additional advantage of these instruments is that they do not always require direct contact with the fluid: as explained, clamp-on models are simply installed on the outside of the pipe, without the need to cut it or shut down the system, while other models—known as in-line—are integrated directly into the pipeline. Although their installation is more invasive, they offer even greater measurement accuracy.

The reliability of these instruments can be affected by factors such as excessive air bubbles or solid particles in the fluid, significant temperature variations, or specific pipe conditions (such as material, wall thickness, or scaling).

Additionally, for proper operation, they often require straight pipe runs before and after the measuring point.

Chose ISOIL Industria = advanced technologies and qualified support for your applications

ISOIL Industria offers a wide range of ultrasonic flow meters based on the transit-time principle, including clamp-on, full-bore, and in-line models, suitable for measuring fluids of any type across a wide range of temperature, pressure, and viscosity applications.

The key application sectors include:

To ensure accurate and reliable measurements with an ultrasonic flow meter, it is essential to adhere to some best installation practices. First, the type of process connection, if available, must be considered.

It is important to ensure that the process conditions fall within the operational limits of the instrument: the flow rate, fluid temperature, and pressure must meet the minimum and maximum values specified by the manufacturer, and the maximum allowable pressure loss must be compatible with the system’s operation. Sufficient straight pipe sections should be provided upstream and downstream of the measuring point (in accordance with the installation manual) to stabilize the flow profile and reduce turbulence.

Ideally, the flow should be upward, and the instrument should not be installed in areas where air bubbles or suspended solids may concentrate.

Finally, the use of provided accessories, such as the magnetic guide for sensor mounting and the thickness gauge for accurately measuring pipe thickness in the case of clamp-on meters, ensures a stable and correct installation.

Another crucial aspect concerns the usage mode: if occasional or temporary monitoring is required, a portable meter such as the IFX-P200, IFX-P210, or IFX-P261 may be preferable, whereas for continuous process monitoring, it is better to opt for fixed clamp-on models like IFX-F100 or IFX-F161, or full-bore instruments like IFX-R, IFX-E3 or IFX-E4.

It is also important to select output signals for integration with industrial supervisory systems (SCADA, PLC, or BMS). Environmental and process conditions also influence the choice: fluid temperature and pressure must remain within the manufacturer’s declared operational limits.

Exceeding these values can compromise not only the measurement accuracy but also the integrity of the sensor itself.

The pipe dimensions are another key parameter: some meters are optimized for small-diameter pipes, while others are designed for large-diameter pipelines.

Additionally, it is important that the pipe is completely full and under pressure during operation: an incomplete fill level may compromise measurement accuracy.

By carefully evaluating all these aspects, it is possible to select the most suitable instrument to meet your measurement needs, maximizing reliability, efficiency, and the durability of your investment. Feel free to contact our specialists for a consultation.